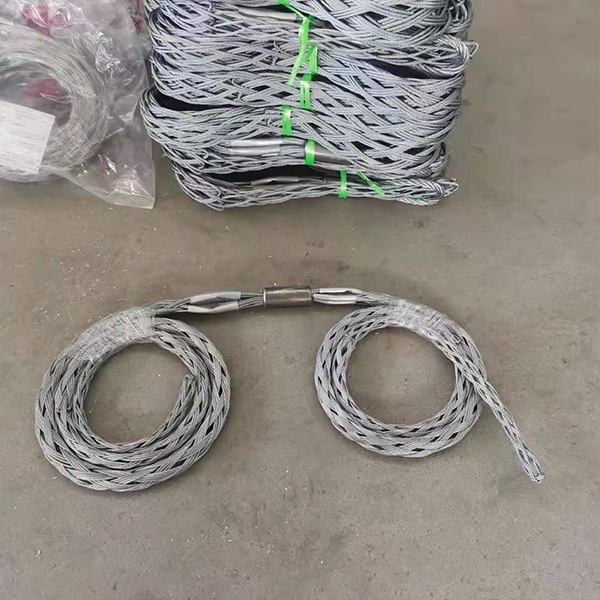

Four-eye Wire Mesh Grips Cable Hose Stockings

Short Description:

Whip Stops are a great way to restrain high pressure hoses. Whip Stops have a unique design that prevents the very real and unpredictable whipping of a high pressure hose during a failure.

| P/N | HOSE OD { INCHES } | HOSE OD MM | Max OD | GRIP LENGTH | EYE LENGTH | TOTAL LENGTH | NUMBER OF PLIES | APPROX WEIGHT | AVERAGE BREAKING STRENGTH |

| 3/8" | 5/16" - 1/2" | 8-14 MM | .70" | 12.5 | 4 | 16.5 | 8X3 | 1/4 LB | 4200LBS |

| 1/2" | 1/2" - 3/4" | 14-20 MM | .85" | 18 | 4.5 | 22.5 | 8X3 | 1/4 LB | 4200LBS |

| 7/8" | 3/4" - 1.1/8" | 20-30 MM | 1.4" | 20 | 6 | 26 | 12X2 | 3/4 LB | 6200LBS |

| 1" | 1.1/8" - 1.1/2" | 30-40 MM | 2" | 27 | 8 | 35 | 12X2 | 1 LB | 12000Lbs |

| 1.1/4" | 1.1/2" - 1.7/8" | 40-50 MM | 2.5" | 32 | 8 | 40 | 12X2 | 1.1/4 LB | 12000Lbs |

| 1.1/2" | 1.7/8" - 2.3/8" | 50-60 MM | 3" | 41 | 11 | 52 | 12X2 | 2.1/4 LBS | 17000 Lbs |

| 2" | 2.3/8" - 2.3/4" | 60-70 MM | 3" | 43 | 11 | 54 | 12X2 | 2.1/2 LBS | 17000 Lbs |

| 2.1/2" | 2.3/4" - 3.3/8" | 70-85 MM | 3.75" | 43 | 13 | 56 | 12X2 | 5.1/4 LBS | 17000 Lbs |

| 3" | 3.3/8" - 3.7/8" | 85-100 MM | 4" | 58 | 17 | 75 | 12X2 | 5.1/4 LBS | 26000LBS |

| 4" | 4.3/4" - 5.1/2" | 120-140 MM | 6.25" | 71 | 19 | 90 | 16X2 | 7.1/2 LBS | 30000LBS |

| 6" | 5.1/2" - 7" | 140-180 MM | 8" | 79 | 19 | 98 | 16X2 | 8 LBS | 30000LBS |

Whip Stops are a great way to restrain high pressure hoses. Whip Stops have a unique design that prevents the very real and unpredictable whipping of a high pressure hose during a failure. Whip Stops are made of woven steel that grip and tighten over a large area of the hose as it suppresses and confines the hose that has ruptured. The length and the number of anchor points can be made to order. For industries that require a tagged system, test certifications and traceability are available

We recommend Whip Stops for any high pressure application, whether it be air, hydraulic, water, frac fluids, slurry, oil, etc.

The Whip Stop has a specially designed braided cable which allows the cable to tighten down on the hose during a failure. Unlike the Whip Check or the steel Hobble Clamp, the Whip Stop will continue tightening down. The double leg anchoring points prevent the hose from whipping side to side making the Whip Stop very desirable where employees are working near high pressure applications.

Whip Socks Uses :

These are the best high-pressure hose restraints available, because the stocking style woven steel grips the hose more securely over a larger area. Abrasion and wear and tear usually take place near fittings, which may result in a rupture. The woven steel can also help prevent abrasion to the hose underneath. These Whip Socks are not restricted to just air hoses, but can be used on any application where high-pressure hoses are used, air, water, hydraulic, slurry, etc.

Cable nets connector (also known as: cable nets, nets, wire mesh cover, middle anchor net, network, cable network, optical fiber net, ground net set) cable net use: electric power construction steel connection when all kinds of aluminium conductor and insulation wire, ground wire, optical fiber, optical cable, cable, can pass the all kinds of steel block, with light weight tensile load is big, not line loss, convenient use, is the most ideal tool in electric power construction.

The Whip Stop hose safety restraint system is designed to significantly reduce the risk of injury caused by a high pressure hose blow-out failure. The magnitude of force caused by a large-diameter pressurized hose can cause fatal injury and be difficult to quickly restrain. Additionally, cleanup and downtime can be costly if hazardous chemicals are being conveyed. The whip stop safety restraint system, also known as a whip sock, will prevent blow back and tightly hold a high pressure hose in check until pressure can be safely decreased.

Whip Stop systems are capable of significantly higher pressure ratings than the standard whip-check or nylon hose safety restraints. The double leg loop ends will also prevent the hose from side to side whipping under pressure.

Hobble clamps are available for a wide variety of pipe diameters and can be custom made to specifically meet your requirements. Whip Stop systems can also be connected directly to one another without a hobble clamp where two hoses are being joined.

Available for hose from 3/8″ to 6″ inside diameters

When installing a Whip Stop Safety Restraint, ensure proper fit by verifying if he diamond-pattern of the braiding is equally proportioned. If the diamonds are longer than they are wide, then the restraint is too big and the hose is at risk of slipping. After installing on the hose, pull on the loop ends to ensure there is no movement or rotation of the hose.

Ensure that the mounting point and any hardware is capable of withstanding the significant force caused by a hose blow-out prior to mounting.

Inspect Whip Stop Safety Restraints regularly, and replace if there is any sign of rust or broken cable strands.

Install any protective spiral wrap or insulation over the Whip Stop Restraint.