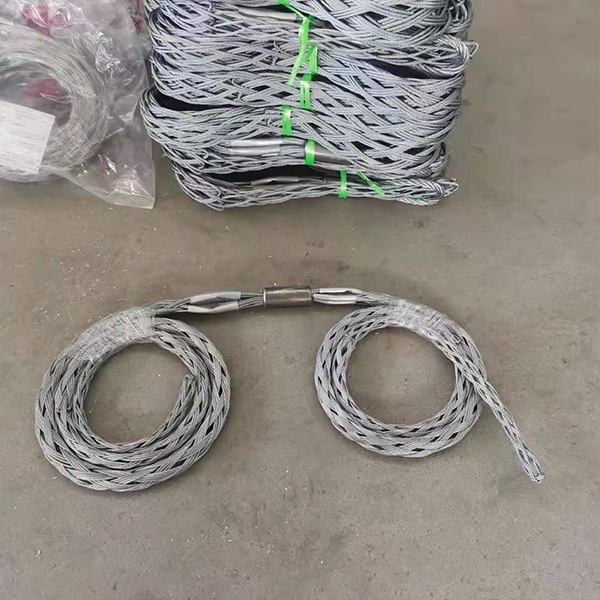

Single Eye Side Pull Type Cable Grips

Short Description:

Whip Stops are a great way to restrain high pressure hoses. Whip Stops have a unique design that prevents the very real and unpredictable whipping of a high pressure hose during a failure.

| P/N | HOSE OD { INCHES } | HOSE OD MM | Max OD | GRIP LENGTH | EYE LENGTH | TOTAL LENGTH | NUMBER OF PLIES | APPROX WEIGHT | AVERAGE BREAKING STRENGTH |

| 3/8" | 5/16" - 1/2" | 8-14 MM | .70" | 12.5 | 4 | 16.5 | 8X3 | 1/4 LB | 4200LBS |

| 1/2" | 1/2" - 3/4" | 14-20 MM | .85" | 18 | 4.5 | 22.5 | 8X3 | 1/4 LB | 4200LBS |

| 7/8" | 3/4" - 1.1/8" | 20-30 MM | 1.4" | 20 | 6 | 26 | 12X2 | 3/4 LB | 6200LBS |

| 1" | 1.1/8" - 1.1/2" | 30-40 MM | 2" | 27 | 8 | 35 | 12X2 | 1 LB | 12000Lbs |

| 1.1/4" | 1.1/2" - 1.7/8" | 40-50 MM | 2.5" | 32 | 8 | 40 | 12X2 | 1.1/4 LB | 12000Lbs |

| 1.1/2" | 1.7/8" - 2.3/8" | 50-60 MM | 3" | 41 | 11 | 52 | 12X2 | 2.1/4 LBS | 17000 Lbs |

| 2" | 2.3/8" - 2.3/4" | 60-70 MM | 3" | 43 | 11 | 54 | 12X2 | 2.1/2 LBS | 17000 Lbs |

| 2.1/2" | 2.3/4" - 3.3/8" | 70-85 MM | 3.75" | 43 | 13 | 56 | 12X2 | 5.1/4 LBS | 17000 Lbs |

| 3" | 3.3/8" - 3.7/8" | 85-100 MM | 4" | 58 | 17 | 75 | 12X2 | 5.1/4 LBS | 26000LBS |

| 4" | 4.3/4" - 5.1/2" | 120-140 MM | 6.25" | 71 | 19 | 90 | 16X2 | 7.1/2 LBS | 30000LBS |

| 6" | 5.1/2" - 7" | 140-180 MM | 8" | 79 | 19 | 98 | 16X2 | 8 LBS | 30000LBS |

Has a specially designed braided cable which allows the cable to tighten down on the hose during a failure. Unlike the WHIP CHECK or the steel Hobble Clamp, the WHIP STOP will continue tightening down. The double leg anchoring points prevent the hose from whipping side to side making the WHIP STOP very desirable where employees are work near high pressure applications.

The whip sock has a unique design that prevents the very real and unpredictable whipping of a high pressure hose during a failure. The real genius behind these new designs is the woven steel that grips and tightens over a large area of the hose as it suppresses and confines the hose that has ruptured.

Use of whip socks:

These are the best high pressure hose restraints available because the sock style braided steel grip hose is safer over a larger area. Wear and tear usually occurs near the fitting, which can lead to breakage. Braided steel can also help prevent wear under the hose. These socks are not only suitable for air hoses, but also for any use of high pressure hoses such as air, water, hydraulic, mud, etc.

The Whip Stop hose safety restraint system is designed to significantly reduce the risk of injury caused by a high pressure hose failure.

The magnitude of force caused by a high pressure hose failure incident can lead to serious injury and can be difficult and dangerous to quickly restrain. Additionally, spills and equipment damage can cause costly cleanup and downtime. The whip stop hose safety restraint system, also known as a whip sock, will hold the hose in check until the operator can safely eliminate the hose pressure.

Double-ear loops on both sides are available for short length hose assemblies. Custom lengths can be designed to meet your exact hose requirement.

In order to ensure that the whip stop system is completely secure, make sure that the pipe, frame, or equipment that the hobble clamp is shackled to is also capable of withstanding the maximum force that your hose failure may cause.

The application of self fusing or rubberized tape where the end of the whip stop meets the hose is recommended when the outside diameter of the hose is within acceptable range but has a looser fit.