Stainless Steel304and316 Whipcheck safety slings

Short Description:

Whipcheck – safety slings are a positive safe – guard for hose connections. These strong steel cables prevent hose whip in case of accidental separation of coupling or clamp device.

Whipchek – safety slings are a positive safe – guard for hose connections. These strong steel cables prevent hose

whip in case of accidental separation of coupling or clamp device. “Whipchek” reaches across the hose fittings to

provide stand-by safety for hose. Spring loaded loops in cable ends open easily to pass over the couplings for firm

grip on hose, as shown. They have been thoroughly tested with years of service.

There are various sizes of Whipcheks manufactured by LH. All materials used for in the manufacturing process conform to SABS & ISO standards, Materials being the cable, ferrules ect.

安全电缆 检查空气软管 风管安全抽检 检查安全电缆是一个积极的安全-保护软管连接.这些坚固的钢缆防止在偶而分离的耦合器或夹紧器的软管。跨越软管配件,为软管提供备用安全。如下图所示,电缆端上的弹簧加载环路很容易打开,通过连接器,使软管获得牢固的抓地力。

它们已经过多年的彻底测试,旨在帮助防止因软管或接头故障而造成的伤害或事故。在软管配件上,有一个试纸器可以提供软管的备用安全性。在连接之前,只要把弹簧拉回去,并把每根软管上的循环滑倒,这样就可以防止软管鞭。

抗冲击安全电缆是一种安全装置,用于防止软管或电缆在软管或接头发生故障时震动。它通常用于使用高压软管或电缆的工业应用,如压缩空气系统或液压设备。鞭子安全电缆由一根坚固的钢缆组成,它与一端的软管或电缆相连,并与另一端的机器或设备相连接。如果软管或配件失效或断开,鞭笞电缆可防止其"鞭笞"或摆动失控,减少附近人员受伤或周围设备损坏的风险。防波安全电缆设计灵活,能够承受压力和极端条件。必须定期检查和更换显示磨损或损坏迹象的抽打电缆,以确保其有效性并维护安全的工作环境。

Whipcheck Safety Cables are available in two cable diameters and a number of different configurations. Whipcheck offer additional safety for compressor hoses in enclosed or critical enviroments.

Whipcheck safety cables offer additional safety for compressor hoses in enclosed or critical environment.

Whipcheck safety cables have been used for many years on air compressor hoses to prevent hose ends from 'whipping' if the coupling blows out of the hose.

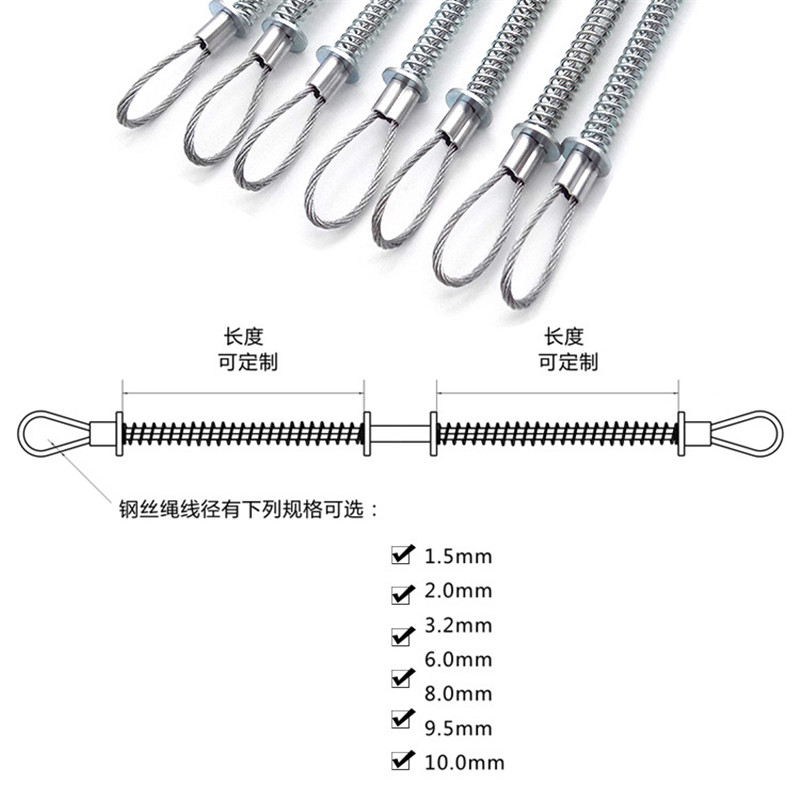

Whipcheck safety cables are available in 1/8" (3.2mm) and 1/4" (6.35mm) cable diameters and in two basic configurations - hose to hose and hose to tool. Hose to Hose are used at the joint between two hose assemblies. Hose to Tool are used at the junction between the hose and the tool but are also very important at the compressor end. The compressed gas can be very hot causing the hose to soften which in turn can lead to an increased possibility of failure.

Fitting the Whipcheck safety cables correctly is critical to their performance. The loop ends should be placed as far down the hose as possible. With the Hose to Hose type, the ferrule in the centre of the Whipcheck should lay at the same point as the joint between the two hoses.

The standard materials of construction are galvanised steel wire, plated steel springs and aluminium ferrules. However, Whipcheck are available in a variety of different styles including Stainless Steel and copper ferrules for marine and applications where the risk of the steel cables sparking is not acceptable.

We also supply large whip check for 4", 6" and 8"nb hose.

We can also offer non-standard versions, made to customer specification, if large quantities are required.

Hose Safety Whip Checks are the trusted industry standard in air hose safety. With 4 adjustable sizes and two different end styles, ware sure to have a cable that fits into your air hose configuration. Spring loop ends adjust to fit snug around a variety of hose diameters.

Size Specifications:

| product name | size | Material | Wire rope diameter(mm) | Overall length(mm) | Spring lengthMM) | Spring outer diameter(mm) | Spring thickness(mm) | Suitable pipe diameter size | Destructive power(KG) | ||

| whipcheck | 1/8" * 20 1/4" | Galvanized carbon steel | 3 | 510 | 180 | 12 | 1.2 | 1/2”-1 1/4” | 700 | ||

| whipcheck | 3/16" *28" | Galvanized carbon steel | 5 | 710 | 240 | 18 | 2.0 | 1/2”-2” | 1400 | ||

| whipcheck | 1/4" *38" | Galvanized carbon steel | 6 | 970 | 350 | 18 | 2.0 | 1 1/2”-3” | 2200 | ||

| whipcheck | 3/8"*44" | Galvanized carbon steel | 10 | 1110 | 310 | 25 | 2.0 | 4” | 3300 | ||

Product construction and testing

LH Safety - Cable Hose Restraints also known as Whip Checks are stocked as well. We recommend whipchecks be used only on AIR HOSES carrying no more than 200 PSI. Any other use is at your own risk.

Usage

Whip check safety cable is designed specially to prevent hose connections from whipping if the hoses or couplings failed to hold. The failure usually occurs with high pressure and will make hoses or equipment shake violently which may cause serious injury for people or the nearby coupling & equipment.

Package